How to Identify and Eliminate Bottlenecks in Manufacturing Processes

Manufacturing bottlenecks, workflow inefficiencies, and production constraints can significantly impact production efficiency and profitability, making their identification and elimination essential for firms looking to improve their economic performance. This comprehensive guide delves into the science of real-world applications and bottleneck detection methods, supported by research studies demonstrating significant improvements in productivity, cost reduction, and overall manufacturing performance.

Key Information Points:

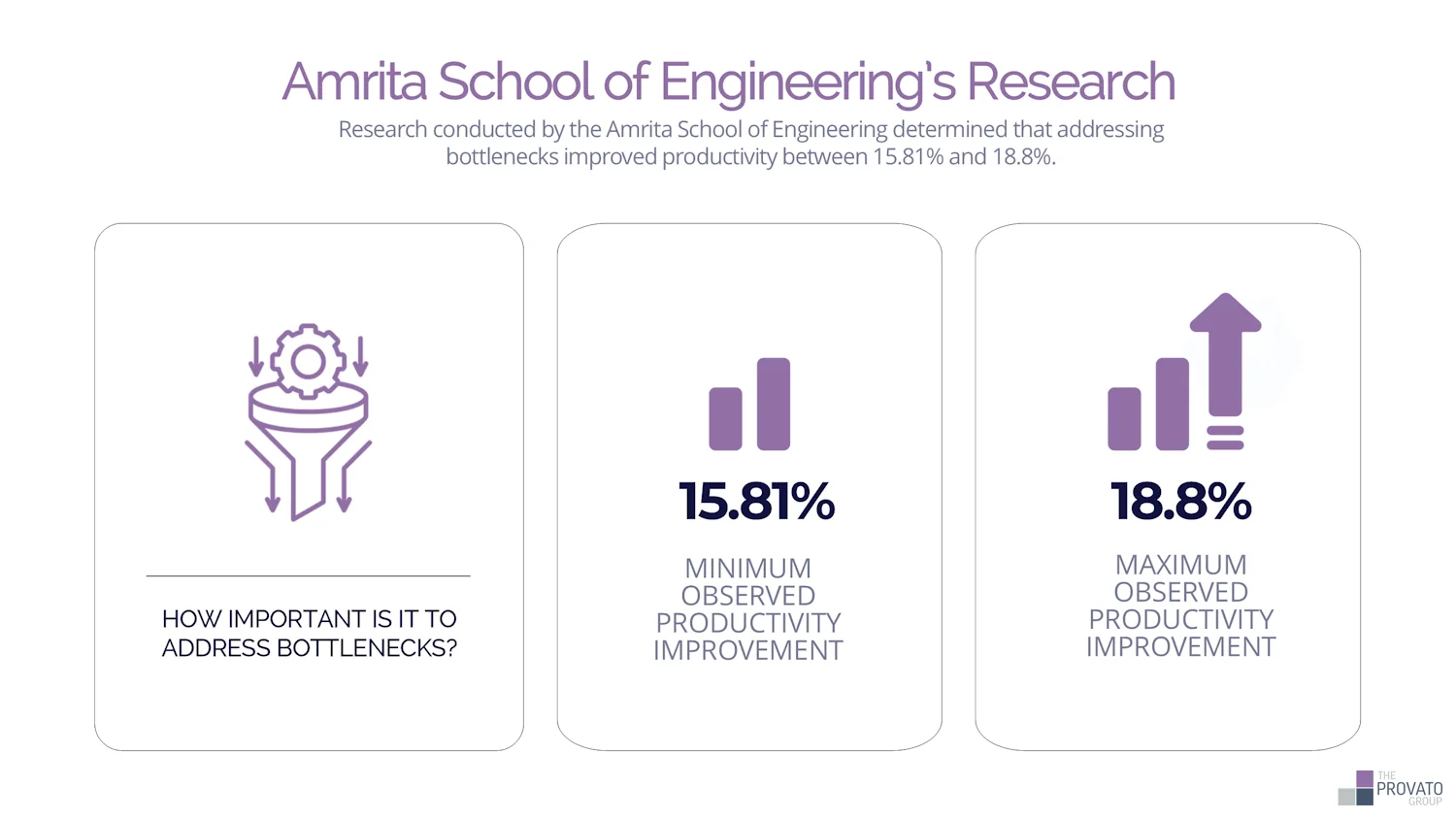

Addressing bottlenecks improved productivity by 15.81-18.8% (Amrita School of Engineering.)

Bottleneck mitigation decreased total manufacturing costs by 19.73% (2019 study.)

Dynamic data-driven approaches showed 30% gain in overall equipment effectiveness.

Predictive analytics achieve 62.53% accuracy vs 24.69% with traditional methods.

Data-driven approaches outperform observation methods by 37.84%.

What is a Bottleneck in Manufacturing?

Bottlenecks are most easily thought of as the narrowest point in a production flow, where work accumulates because it can not be completed as quickly as it arrives from the upstream processes. They will limit throughput, increase upstream Work-In-Progress (WIP), increase production lead times until they are resolved.

In the research paper “Economic analysis of production bottlenecks” by Stephen Lawrence (College of Business and Administration, University of Colorado) and Arnold Buss (Operations Research Department, Naval Postgraduate School) a bottleneck is defined as a point of congestion in the manufacturing process that causes the required resources and capacity to be less than the demand. Lawrence and Buss further elaborate that a bottleneck can be thought of as any process that limits throughput, acting as general blockades to increased output that cause inventories to build up in different places and times.

Why is Bottleneck Detection Important in Manufacturing?

Bottleneck detection helps improve efficiency, increase throughput, improve quality, promote efficient resource allocation, and reduce costs associated with manufacturing processes.

Research conducted by the Amrita School of Engineering determined that addressing bottlenecks improved productivity between 15.81% and 18.8%. A bottleneck that’s unaddressed will lead to more than just a slow production flow and production delays—it can also increase costs, reduce profit, and hurt customer satisfaction and relations.

A 2019 study from the Department of Management Science and Engineering in China found that mitigating bottlenecks decrease the total cost of manufacturing by 19.73%. M. Hajmirfattahtabrizi and H. Song were able to demonstrate that the system improvement from bottleneck mitigation came with no negative effects or disturbances.

What Are the Different Types of Bottlenecks in Manufacturing?

Bottlenecks can be categorized into several types, each having a different impact on production flow.

- Process: When processes are poorly designed, they cause delays between manufacturing stages.

- Machine: Old, slower, and less efficient machines will impact throughput. This includes machines that break down frequently due to their age or ill-state of repair. Machine learning systems can aid in predicting maintenance requirements.

- Labor: Limited availability of workers with specialized skills will lead to slower production rates.

- Supply Chain: The inconsistent delivery, or unavailability, of raw materials will impact input flow for manufacturing to begin. Technology such as logistics tracking systems can help improve these outcomes.

- Quality: When quality checks are too time-consuming due to high defect rates, overall throughput is slowed by products that need to be reprocessed.

- Logistical: Refers to limited capacity, and inefficient storage or movement of materials throughout a facility. Scheduling software can help coordinate the movement of these materials to improve throughput.

- Information: Poor information flow can lead to slower decision making. This is often addressed with custom manufacturing software designed to create a cohesive information ecosystem within your plant.

- Regularity: Approval of documentation requirements will act as bottlenecks. Software can be designed to streamline documentation will reduce the negative effects of regulatory compliance.

- Changeover: High product variability, or long equipment setup times will impact production time and volume.

Beyond those categories, bottlenecks can also be separated into two more groups: Physical and Process.

Physical vs Process Bottlenecks

The main difference between physical and process bottlenecks is that physical bottlenecks are caused by tangible, hardware related limitations, while process bottlenecks are constraints caused by how the work is getting done (procedures, workflows, or software issues.)

Physical bottlenecks can be reduced and optimized with software solutions that allow for smart equipment integration. Beyond upgrading machinery, reconfiguring plant layouts, and incorporating automation solutions, custom software will allow you to implement predictive maintenance and real-time monitoring systems to ensure that your equipment operates at peak performance, reducing downtime and optimizing throughput.

Process bottlenecks can be optimized and improved upon with custom software designed specifically for your manufacturing operations to streamline workflows, automate repetitive tasks, offer real-time data and analytics to plant management, and improve communication via system integration.

Where in the Manufacturing Process Can Bottlenecks Occur?

According to their 2021 study, the University of Michigan’s Department of Mechanical Engineering found bottlenecks are frequently non-static. X Lai, H Shui, D Ding, and J Ni determined that bottlenecks would shift from station to station throughout a production cycle and require dynamic bottleneck detection methods to mitigate their negative impact on manufacturing throughput.

That is to say that bottlenecks can occur at any stage during production, from material sourcing and supply to packaging and shipping. The key to managing them lies in dynamic detection and responsive strategies. Custom software developed exclusively for your processes and industry can help you not only identify where current bottlenecks are occurring but also predict and prevent future ones.

What Are the Signs of Bottlenecks in Manufacturing?

Signs that bottlenecks are becoming a problem in your manufacturing process include the accumulation of work-in-progress (WIP) inventory, increase cycle times, excessive overtime, increased idle time, and delayed fulfillment. Unfortunately, these signs, or symptoms, can often lead to compounding issues that can make them hard to spot until there is already a greater impact that is slowing down your business, hurting productivity and profitability, and negatively impacting customer relationships.

While signs can be helpful, relying on only observable indicators will not catch bottlenecks until they’ve already impacted production. A 2018 study done by the Department of Industrial and Materials Science and the Department of Computer Science and Engineering at Chalmers University of Technology in Gothenburg, Sweden found that a data-driven algorithm to check the states of machines and the corresponding time stamp outperformed purely observation methods in predicting bottlenecks by a staggering 37.84%.

Custom data-driven applications can be combined with traditional observation methods by manufacturers to not only detect bottlenecks but predict them.

How Often can Bottlenecks Occur in the Manufacturing Process?

Bottlenecks can occur at any time and as frequently as daily – or even hourly – depending on the dynamics of your operation. In a study from 2009 titled “Real time production improvement through bottleneck control”, Lin Li, Qing Chang, Jun Ni, and Stephan Biller found that the frequency of short-term production constraints could be reduced through the use of initial buffer adjustment and maintenance task prioritization.

Custom manufacturing software can help you plan both initial buffer adjustments and maintenance task prioritization by analyzing your historical production data, predicting potential bottlenecks based on previously demonstrated points of failure, and optimizing resource allocation across your manufacturing processes.

What Are the Common Causes of Manufacturing Bottlenecks?

In a 2021 study, researchers from the Department Mechanical Engineering, Covenant University found that inefficient or incapable process design was the most common cause of manufacturing bottlenecks, representing 25% of the total. The main categories of manufacturing bottlenecks are man-machine interference, logistics, line dedication, weather, manufacturing processes, process capability, communication, and resources.

| Cause | Factor Loading | Category |

|---|---|---|

| Process technology | 0.878 | Man-machine interface |

| Choice of location | 0.874 | Logistics |

| Processing rate | 0.872 | Line dedication |

| Environmental factors | 0.854 | Weather |

| Raw materials flow | 0.834 | Manufacturing process |

| Equipment failure | 0.832 | Process capability |

| Material unavailability | 0.811 | Process capability |

| Random events | 0.812 | Manufacturing process |

| Information and time-of-usage | 0.802 | Communication |

| Operations | 0.780 | Process capability |

| Resource constraints | 0.752 | Resources |

| Facility layout | 0.750 | Man-machine interface |

| Market demand | 0.739 | Process capability |

| AGV issues | 0.732 | Manufacturing process |

| Facility limitations | 0.729 | Resources |

| Ergonomic hazards | 0.711 | Man-machine interface |

| Product mix change | 0.566 | Line dedication |

| Transportation time | 0.532 | Logistics |

How Do Bottlenecks Impact Production Efficiency and Profitability?

Bottlenecks in manufacturing can have a large impact on both the efficiency and profitability of a given process. In a 2016 study funded by the National Science Foundation, researchers were able to increase part production, daily profit by $9,431.12, and reduce energy consumption by 716.74 kWh per day by identifying and mitigating the Energy Profit Bottleneck (EP-BN). Their results are impressive as the EP-BN considers both energy costs and production throughput, making it more comprehensive than traditional throughput bottlenecks.

How Do Bottlenecks Impact Manufacturing Production Flow and Cycle Time?

The identification and elimination of bottlenecks have a significant impact on the production flow and cycle time of a company’s production system. A 2018 study done by Poland’s Bialystok University of Technology observed that by addressing bottlenecks in the manufacturing production cycle, they were able to raise total production between 56.2% and 89.4% and reduce total cycle time from 5.56 seconds to 3.08 seconds.

What Methods and Tools Should I Use to Detect Bottlenecks Early?

Research has shown that the most useful methods of detecting manufacturing bottlenecks early are data-driven approaches, machine learning techniques, statistical frameworks, and dynamic bottleneck identification. In a 2009 study by authors from the University of Michigan’s Department of Mechanical Engineer, and the Manufacturing Systems Research Laboratory of the General Motors Research and Development Center, simulation-based bottleneck detection has limitations, where data-driven detection proved to be more effective at identifying both short and long-term bottlenecks. This data-driven bottleneck detection methodology was then later verified by both analytical and simulation models. A more recent 2021 study from the University of Michigan’s Department of Mechanical Engineering demonstrated that a dynamic data-driven approach to bottleneck detection produced a 30% gain in overall equipment effectiveness in an automotive powertrain assembly line. While there are multiple dynamic data-drive methods that can be used, the 2021 study’s authors Xingjian Lai, Huanyi Shui, Daoxia Ding, and Jun Ni used the turning point method to provide the needed context for their research.

What is Real-Time, Dynamic Data-Driven Bottleneck Detection?

Dynamic data-driven bottleneck detection is an umbrella of methods that use real-time data to detect throughput issues in production processes. It is considered superior to simulation-based methods due to its use of data solely collected from manufacturing systems versus simulation methods that rely on approximations. Common methods of dynamic data-driven bottleneck detection are turning point method, active period method, shifting bottleneck detection algorithms, machine learning-based approaches using time series analysis, and process mining techniques.

The tools used for data-driven bottleneck detection generally fall into two main categories: Data Collection and Integration Tools, and Data Analysis and Predictive Tools.

Data Collection and Integration Tools

These systems gather comprehensive real-time data that drives bottleneck detection.

- Computerized Maintenance Management Systems (CMMS): Centralizes maintenance information and streamlines maintenance operations. CMMS provides real-time data on equipment health, maintenance schedules, and historical failure data.

- Plant Maintenance Decision Support Systems (PMDSS): Offers strategic support for maintenance decisions at the plant level, often incorporating data analytics to prioritize maintenance activities that impact production the most.

- Industrial Internet of Things (IIoT) Devices: Sensors and connected devices that collect real-time operational data.

- Manufacturing Execution Systems (MES) and SCADA Systems: As previously mentioned, these systems collect and integrate data across the manufacturing process.

Data Analysis and Predictive Tools

These tools analyze data, predict issues, and visualize insights for informed decision-making.

- Process Mining Tools: Analyze event logs from IT systems to reconstruct actual process flows, identifying inefficiencies and bottlenecks.

- Profiling Tools: Measure performance metrics to identify areas needing improvement.

- Machine Learning and AI Tools (Including LSTM Networks): Advanced algorithms that analyze historical and real-time data to predict future bottlenecks.

- Long Short-Term Memory (LSTM) Networks: A type of recurrent neural network capable of learning order dependence in sequence prediction problems, making them suitable for time-series data analysis in manufacturing.

- Business Intelligence (BI) Tools: Visualize complex data for easier interpretation, aiding in quick decision-making.

How Custom Manufacturing Software Development Unifies Bottleneck Detection

Custom software proves the ability to combine and aggregate data from multiple disparate sources allowing manufacturing companies to carry out comprehensive analysis, train LSTM networks with their specific and unique historical production data, and capture niche operational metrics that would not be possible with off-the-shelf solutions.

Once systems are in place to gather real-time data, manufacturing software development services help companies build custom solutions to identify and eliminate of production bottlenecks by providing a custom tailored, unified platform that improves data flow, analysis, and decision-making processes. Regularly assessing the performance of your manufacturing software, if you already have a solution in place, will help you ensure that it continues to provide the needed level of efficiency and flexibility to identify bottlenecks as manufacturing processes continue to evolve.

How Can Predictive Analytics Help Identify Potential Bottlenecks Before They Occur?

Predictive analytics allow manufacturers to manage bottlenecks more effectively by both identifying and framing strategies to address future probable bottlenecks before they become an issue, as well as providing information on non-probable bottlenecks.

In a 2018 study conducted by the Chalmers University of Technology’s Department of Industrial and Materials Science as well as the Department of Computer Science and Engineering, researchers were able to predict bottlenecks with 62.53% accuracy using predictive analytics, versus just 24.69% of the time with traditional methods. The additional insights gained from predictive analytics aid with production planning and management, helping achieve the goal of improving throughput and reducing waste.

What Are the Steps to identify and Eliminate Manufacturing Bottlenecks?

Identifying and eliminating manufacturing bottlenecks involve implementing data collection and integration tools and utilizing data analysis and predictive tools to apply detection methods in real-time. Oftentimes, manufacturers will need to develop and implement targeted solutions specific to their manufacturing processes, including custom software applications and predictive maintenance systems, to streamline workflows and improve overall performance, productivity, and throughput.

- Process Mapping: Create a flow chart that maps out your entire manufacturing process from the acquisition of raw materials to the finished product.

- Implementing Collection and Analysis Tools: Use process mining, profiling, machine learning and AI tools to allow for the collection of data.

- Apply Data-Driven Detection Methods: Implement the collection of real-time data from your manufacturing process.

- Analyze Collected Data to Identify Bottlenecks: Look for signs such as work-in-progress (WIP) inventory accumulation, cycle times, overtime, idle time, or delayed fulfillment. Use predictive analytics to forecast potential bottlenecks.

- Categorize Bottlenecks: Determine if the bottlenecks found are physical- or process-related and classify them into specific types (e.g., process, labor, supply chain, quality).

- Prioritize Bottlenecks Based on Impact: Consider factors like production efficiency, profitability, and energy consumption. Focus on bottlenecks with the highest potential for improvement.

- Develop and Implement Solutions: For physical bottlenecks consider equipment upgrades, plant layout reconfiguration, or automation. For process bottlenecks streamline workflows, automate repetitive tasks, improve communication.

- Use Custom Software Solutions: Develop tailored applications to address industry-specific bottlenecks, implement predictive maintenance systems, and create real-time monitoring and analytics dashboards.

The Role Integrated Software Solutions Play in Bottleneck Identification and Elimination

Manufacturing bottlenecks, as we’ve explored throughout this article, present complex challenges that require sophisticated detection and resolution approaches. The key difference between traditional bottleneck management and modern integrated software solutions lies in their ability to connect previously siloed data sources, apply machine learning to facility-specific patterns, automate routine decision-making, and provide contextual alerts and recommendations.

Beyond Detection: Proactive Optimization

The true power of integrated software solutions extends beyond bottleneck detection and into how it impacts day to day plant operations.

For production scheduling, teams now prevent future issues instead of reviewing past ones. Dynamic dashboards predict bottleneck risks for the next 24–48 hours, and AI-driven recommendations optimize resource allocation.

In maintenance planning, timing adapts to actual equipment wear rather than fixed schedules. Predictive algorithms balance maintenance needs with production demands, suggesting optimal repair times based on current orders and capacity.

In resource allocation, machine learning algorithms continuously optimize workflows. Staff assignments adjust based on real-time production needs, and energy usage automatically optimizes according to production patterns.

Learning and Evolving

Perhaps most importantly, these systems learn and improve over time. Each day’s production data enriches the AI models, making predictions more accurate and recommendations more relevant. The result is a manufacturing environment that doesn’t just solve problems—it prevents them from occurring in the first place.

Could Integrated Software Solutions Help You Optimize Manufacturing Processes?

Our application development team specializes in all aspects of creating and supporting applications that streamline your manufacturing processes through process-specific intelligence and optimization, seamless systems integration, and scalable performance solutions.